Inventory Control

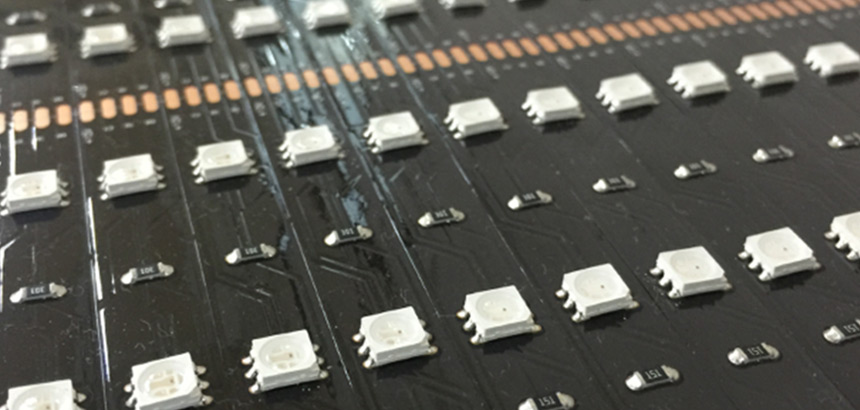

A corner of our inventory area.

Every LED product we manufacture is made of different raw components such as LED chips. resistors, wires & housings. Each component is stored in these small inventory bins with an unique SKU identification code as well as the location code. Our manufacturing system automatically locates the components and required quantity we need for production according to bill of materials (BOM). All components are being real-time monitored and recorded during manufacturing.